Modified Vitiation in a MILD Combustion Furnace

发布时间: 2018-05-15 03:24:00

Energy & Fuels, 26(1), 265-277

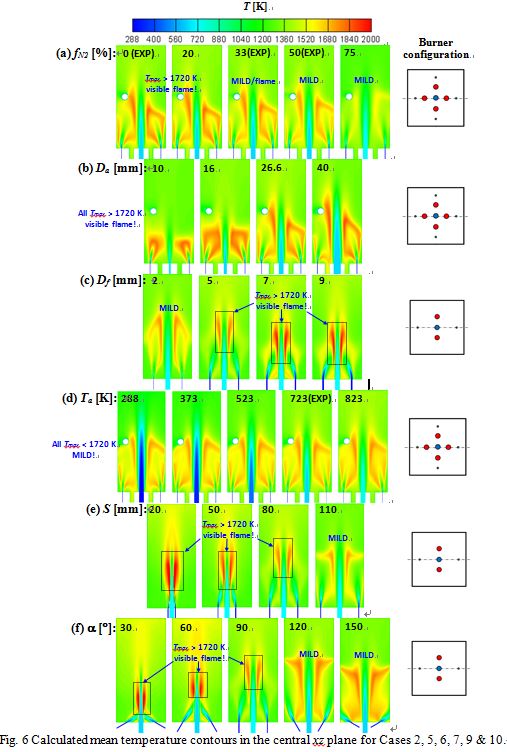

This paper reports on the effects of various operational and geometric parameters on mixing and vitiation in a laboratory-scale furnace operating with natural gas and under the moderate or intense low-oxygen dilution (MILD) regime. The study is carried out through numerical modeling. Seven independent parameters are considered: i.e., mass fraction ( f ) of fuel diluents (CO2 and N2), air preheat temperature (Ta), global equivalence ratio (f ), air nozzle exit diameter (Da), fuel nozzle exit diameter (Df), fuel-air nozzles separation distance (S) and fuel injection angle from the furnace floor (a). The modeling is initially verified through a comparison with measurements of Szegö et al. (Combust. Flame 2008, 154, 281-295) in the same furnace geometry.

It is shown that varying each of the parameters f, f, Da, Df, S and a can considerably influence the fuel jet penetration distance and the recirculation rate of the exhaust gas, two important quantities for establishing the MILD combustion. Relatively, the geometric parameters Da, Df, S and a play more effective roles in controlling the vitiation rate and hence “flame” characteristics. Also, it is revealed that influences of all the parameters except S and a can be represented by that of the ratio of the fuel injection momentum to the air injection momentum.